|

Advantages Of Ductile Iron

Why Ductile Iron?

Ductile Iron not only retains all of Gray Iron’s attractive

qualities, such as machinability and corrosion resistance, but also

provides

additional strength, toughness, and ductility. Although its chemical

properties are similar to those of Gray Iron, Ductile Iron

incorporates

significant casting refinements, additional metallurgical processes,

and superior quality control.

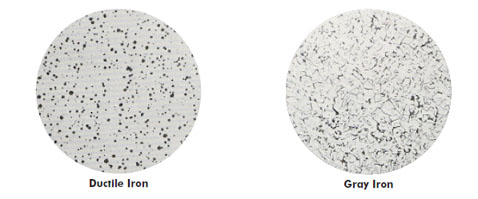

Ductile Iron also differs from Gray Iron in that its graphite form

is spheroidal, or nodular, instead of the flake form found in Gray

Iron.

This

change in graphite form is accomplished by adding an inoculant,

usually magnesium, to molten iron of appropriate composition during

manufacture.

Due

to its spheroidal graphite form, Ductile Iron has approximately

twice the strength of Gray Iron as determined by tensile, beam,ring

bending, and bursting tests. Its impact strength and elongation are

many times greater than Gray Iron’s.

As

these photomicrographs show, Ductile Iron (above left) differs from

Gray Iron (above right) in that

its

graphite is spheroidal, or nodular, instead of the flake form found

in Gray Iron. Ductile’s greater

strength, ductility, and toughness are due to this change in

microstructure.

Ductile Iron Gray Iron

Ductile Iron Advantages:

|

|

Exhibits Tremendous Tensile Strength |

|

|

Withstands Severe Crushing Loads |

|

|

Has Great Beam Strength |

|

|

Is Corrosion Resistant |

|

|

Has Extremely High Impact Resistance |

|

|

Demonstrates Tremendous Bursting Strength |

|

|

Is Easy to Install |

|

|

Is Virtually Maintenance Free |

|

|

Offers Impressive Energy Savings |